Development has hit almost every sector of the world. Be it food, infrastructure, gadgets, fashion, or anything your mind can think of. It has also moderated the printing world. Printing is a process of reproducing text or images using a sample. This process requires a technique and a medium for printing.

Starting from Woodblock printing in 200 AD, till today, we have come a long way. The latest mode of printing is Digital printing that originated in 1991. It is evolving continuously and is coming up with new techniques and improved quality every day.

What is The Digital Printing Process?

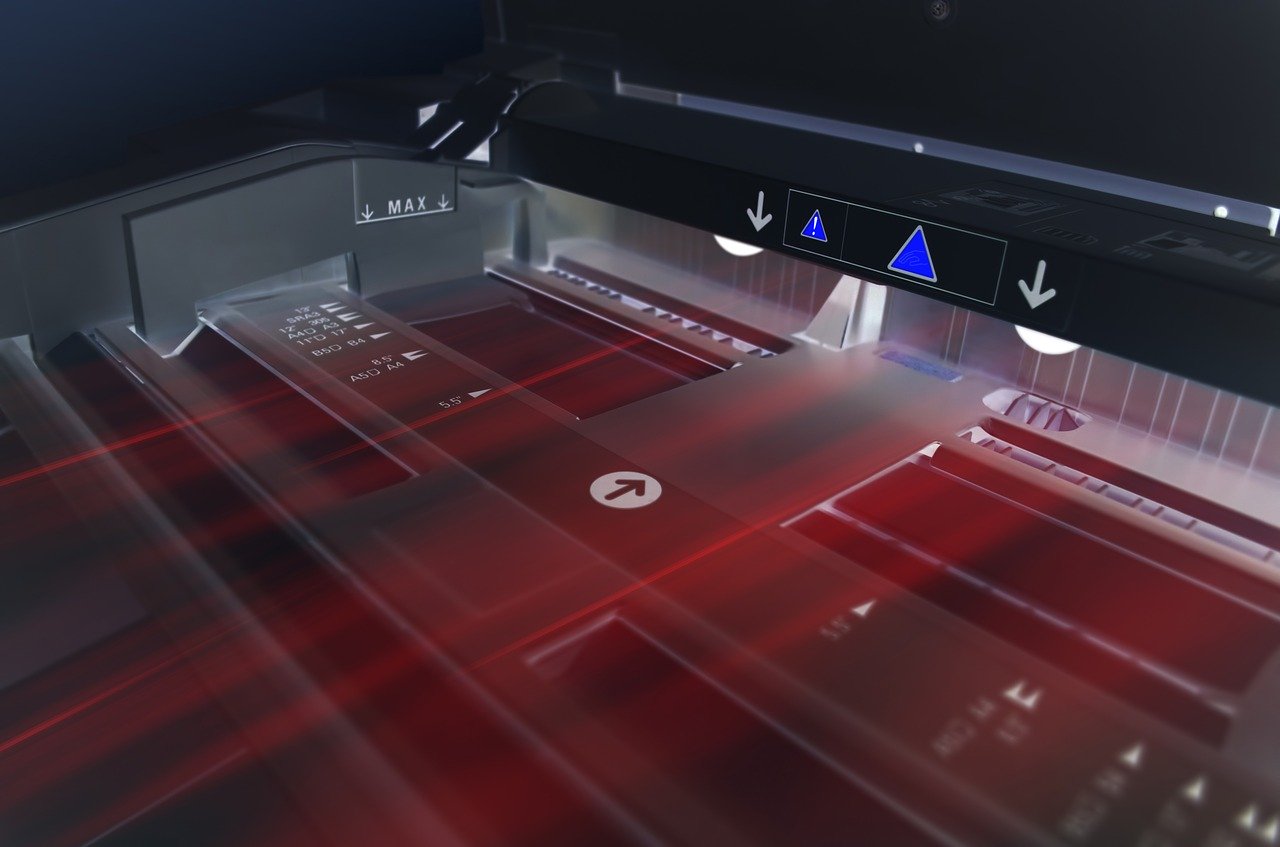

It is the process of printing on different kinds of media using a digitally processed image. The media includes paper, plastic, acrylic, and other substrates. This modern method came into being after Dot matrix printing, Xerography, Dye-sublimation, Thermal printing, 3D printing, Solid ink printing.

It has efficiently replaced the processes mentioned above. This process does not involve many manual steps like other conventional methods which makes it more error-free. Digital printing is an effortless and highly effective way of printing, but it sometimes lacks affordability.

The printers that support digital printing are inkjet printers and laser printers. They drop designs on almost all kinds of substrates and ensure firm adherence.

Benefits of Digital Printing

Digital printing is one of the most popular methods of printing. Printing is an essential part of every business. Businesses advertise themselves using banners, pamphlets, newspapers, etc. All these means of advertisement require the printing of their content on some medium. It is sometimes difficult for a business owner to choose the right way of letting this happen. Before deciding upon the most suitable printing method for your brand, you need to go through some benefits of digital printing:

- High-Quality finish: Quality is never compromised when it comes to digital printing. You get excellent quality for the money you spend. Since this technique involves machine work, it has to have the best standard.

- Quick Turnaround time: Quick delivery is another important aspect. The whole process is performed without the involvement of plates; hence the turnaround time is less than other processes.

- Cost-effective: This automatic process reduces the labour cost. Moreover, the printing plates manufacturing cost is also eliminated. The overall setup cost is less for shorter runs.

- Consistency: While working with machines, every print that comes out is uniform—fewer chances of error and no difference among the multiple prints of the same series.

- Eco-friendly: This process has proven to be eco-friendly because it does not include extra film plates or photo chemicals. There are no prepress steps in the digital printing process.

The Digital Printing Process

This method involves the following steps:

Step 1:

The Digital printing process begins with getting the design ready for printing. Some customers create their designs, and some outsource the designing job. Design is prepared based on the instructions and requirements of the customer. Detailed meetings are held to incorporate changes and alter the designs. The outcome of the process is then forwarded to the customer.

Step 2:

After the final version of the image is approved by the customer, the image is brought into the appropriate format. The correctness of the format is compulsory because it gets easier for the printer to recognise the right product and print it.

Step 3:

This step involves cleaning. Cleaning is of utmost importance while working. It prevents the printer heads from drying out and hence saves it from damage. This step has to be repeated after every 100th iteration or sometimes sooner. It all depends on the amount of colour in print.

Step 4:

Some quality checks are to be carried out prior to the printing process:

- To avoid ink spillage, the drum that collects the waste ink after every iteration must be emptied timely.

- With every restart, the printer uses a certain amount of cleaner which is stored in a container in the printer. A check has to be maintained on the amount of the cleaner in the container. It must not be empty anytime.

- To avoid damage to the print heads, ink’s temperature should be monitored. The ideal temperature is within a range of 20 – 25 degrees centigrade. If the temperature exceeds, the print heads are harmed.

Step 5:

After all the quality checks are carried out, this step involves one complete glance over all the previous work done. The customer’s artwork is not ready to be printed.

Step 6:

Pallets are required to hold the product. They come in two different sizes and are used according to the requirement of the product. The product is laid out on the pallet and is ready for printing.

Step 7:

In this step, it is made sure that the product is laid flat on the board without any creases. Even a single crease would distort the printing process.

Step 8:

The actual printing begins now. The printer head sprays the coloured design on to the product moving from side to side.

Step 9:

To ensure secured adherence, the product is removed from the pallet and dried under a huge dryer at a specific temperature. This step bakes the design smoothly and strongly on to the product.

Step 10:

Last but not the least step is to check the product to ensure excellent quality and high-end finish. After quality assurance, the product is packed with care and dispatched.

Conclusion

Digital printing in Dubai is very popular. Many businesses opt for this process because it is a convenient yet highly effective method of printing. Industry experts look up to companies that offer good quality printing on all kinds of substrates. This method saves huge on the labor side and improves capability.

Time is another advantage in this field. Short print runs are done excellently on-demand in the least amount of time. The aforementioned 10 step procedure is ideal for businesses who are in search of modern and the finest quality prints. For quick personalisation and modifications, digital printing is the only way to go.